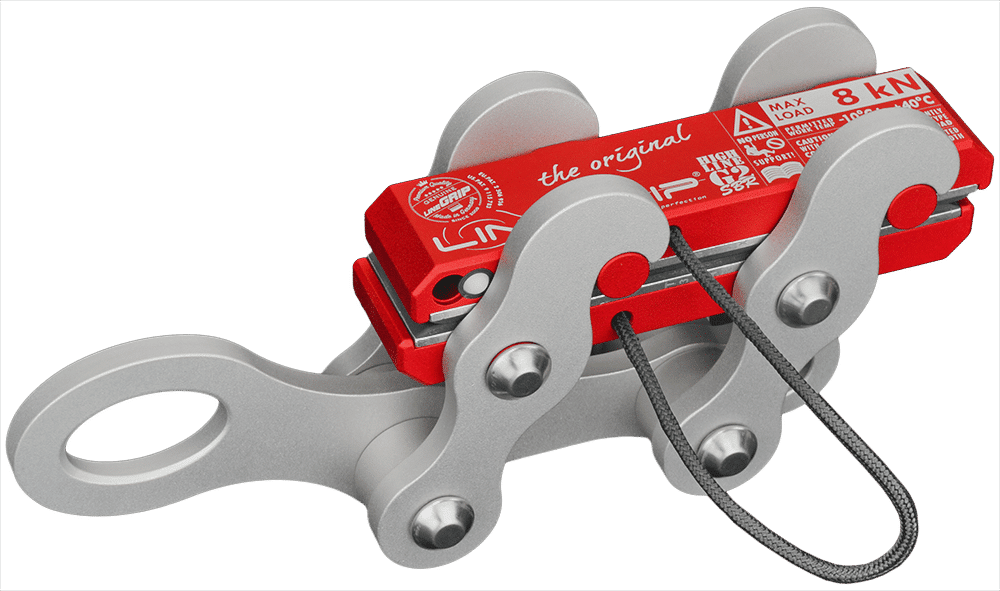

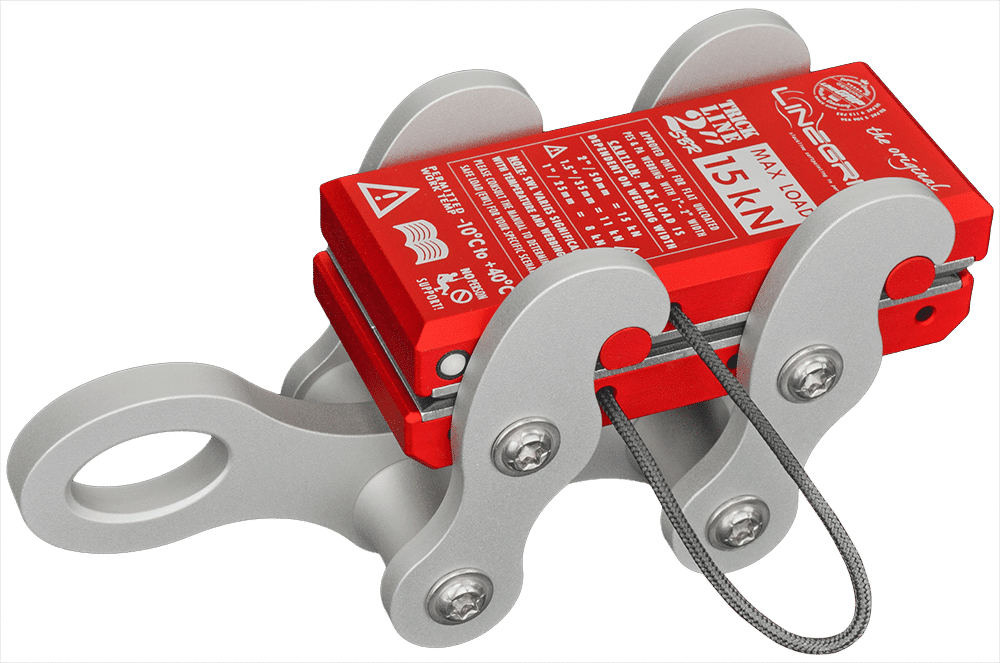

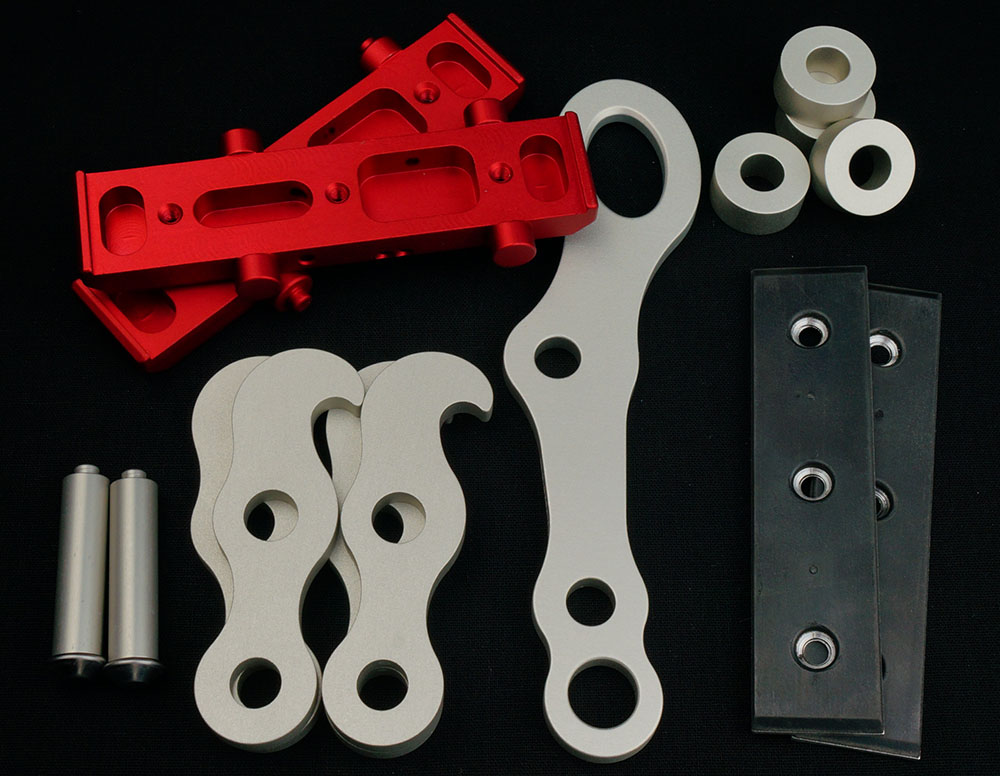

lineGrip Common Features

These features apply to all lineGrips.

You may find links to pages with model specific features and specs in the Products menu in the top navigation bar, or in the “More Information” tab on each product page.

Design Parameters

- Full aviation aluminum construction

- Great working temperature range

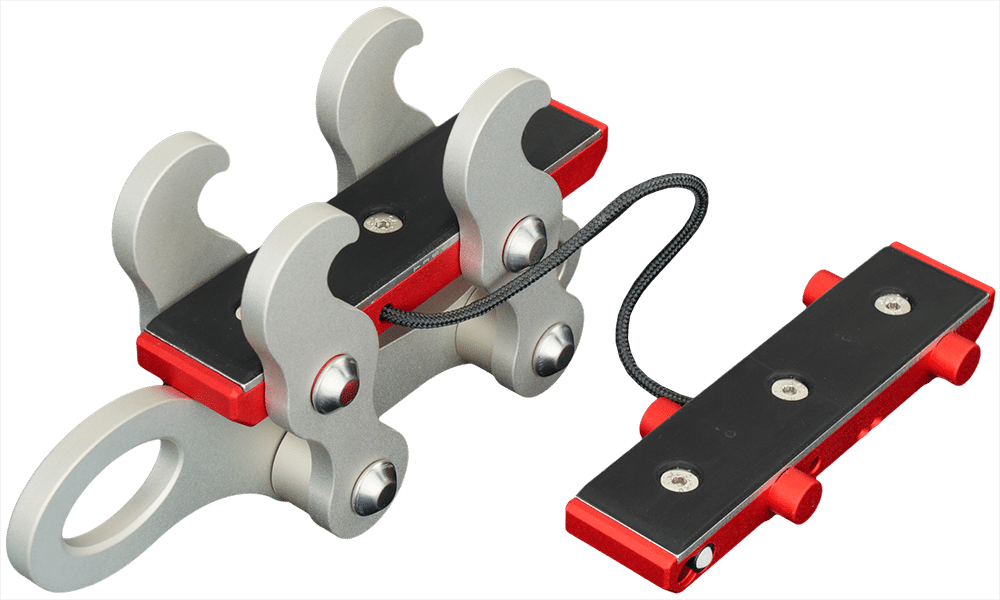

- Replaceable rubber plates

- Tangle free Dyneema plate tether cord

- Clamping plate retainer machanism

- Extra large load eye

- lineGrip cluster capability

- Compact size and light weight

Best Value for Money

- Virtually Service Free

- Replaceable Wear Parts

- High Lifespan

- Available in Multiple Colors

- One Unit for 16mm – 52mm Webbing

- Lifetime warranty and service guarantee

Intuitive and Hassle Free Handling

- Easy and fast patented “clip and go” technology

- Attaches to tensioned and slack webbing in seconds

- Repositioning simply by the push of a finger

- No unlocking or loosening necessary for reposition

- Auto locking in any situation – simply attach and start to tension

- Fumble free auto release removal – unload, swing open and unlatch

- Removes from tensioned and slack webbing in seconds

- Auto adjusts to any webbing thickness from 1-5 mm

- Handles any webbing type (in some cases with load limitation)

- Immune to water, snow and ice (limited function in dust, dirt, heat & cold)

- Equipped with error avoiding systems

- Plate locking system – won’t unlatch inadvertently, once attached

Proven Reliability and Quality

- The one and only original lineGrip

- Patented industry leading technology

- Proven quality, and well tested since 2009

- Perfected through 8 years of development

- Valued today by almost 10000 users around the globe

- 99.9% customer satisfaction

- Reliable functionality in almost any scenario

State of the Art Quality Manufacturing

- Precision CNC milled custom components

- Full aviation aluminum alloy AW7075-T651 construction

- CNC lathed AISI 303 stainless steel load bearing bolts

- Vibration ground rounded edges, to protect your precious webbing

- Steel ball shot peened parts, for hardened surface and satin finish

- High quality anodizing for durability and lubrication free smooth motion

- ISO-9001 certified and quality controlled component production cycle

- 100% designed, manufactured, and assembled in Germany