Our mission is to make slackline rigging safer, easier and faster!

Rigging longlines, and particularly highlines, is a tedious and time consuming task, which is associated with high effort, and numerous risks. A tool such as the lineGrip can significantly simplify and speed up this chore, and make it more secure.

Knowing this, we move heaven and earth, to provide you with the best conceivable tool to take this load off your shoulders. Albeit, the lineGrip will not rig the slackline for you, but it will definitely help turn rigging from a potentially frustrating, to a more enjoyable task.

Asset protection through durability, and guarantee for lifetime warranty and free service.

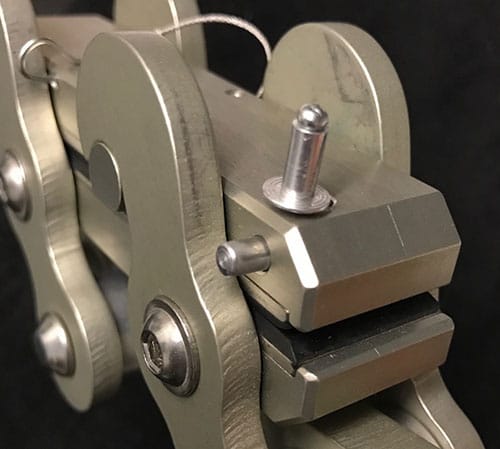

Our commitment does not end with the development of a good and functional product. We at lineGrip Corp. do everything we can, to assure you will enjoy your precious equipment literally forever. We constantly strive for a product quality, that will ensure you won’t ever need to replace your lineGrip with another one due to wear, fatigue, or failure. When used as designated, we guarantee that nothing but the wear parts – the rubber plates – must be replaced over time, no matter how often you use your unit.

Given the case you should ever be concerned about the function, reliability, or safety of your lineGrip, we will verify, check, and service your unit free of charge, anytime you request us to do so.

Learn more about the lineGrip lifetime warranty and service policy >

There is always room for improvement, and customer support is of highest importance.

It might not seem to be a fulltime job to manage “one single” product such as the lineGrip, but it is – after all we serve each and every lineGripper, and supply all dealers carrying the lineGrip worldwide, from this head office.

It’s not only manufacturing and sales though. Most of our time is consumed by optimizing & perfecting the existing products, and developing & testing new variations, that are requested by the slackline community. We constantly monitor the community, and are in close contact with many of the best and most dedicated slackliners around the globe, to make sure, that we sense and anticipate what is important for them.

The lineGrip core team consists of two people.

Arthur Riedrich, the owner of lineGrip Corp. Ltd. and his son Andy (Mr. lineGrip) Riedrich, CEO, inventor of the lineGrip and founder of slackPro! (the former manufacturer and distributor of the lineGrip). SlackPro! was discontinued in December 2015 and transferred all business to lineGrip Corp., which was founded in summer 2015 and henceforth continues lineGrip development, production, sales and support.

The great global demand for lineGrips can be managed by only two people through:

1. Highest product quality and customer satisfaction.

We register less than 0,01% in complaints, returns and defects, which reduces complaint management to a negligible minimum. The lineGrip’s great reliability, its intuitive functionality, and its near to error proof design, as well as the intricately detailed instruction manual, all contribute to making customer support an easily manageable task.

2. A perfectly honed and synchronized outsourcing strategy.

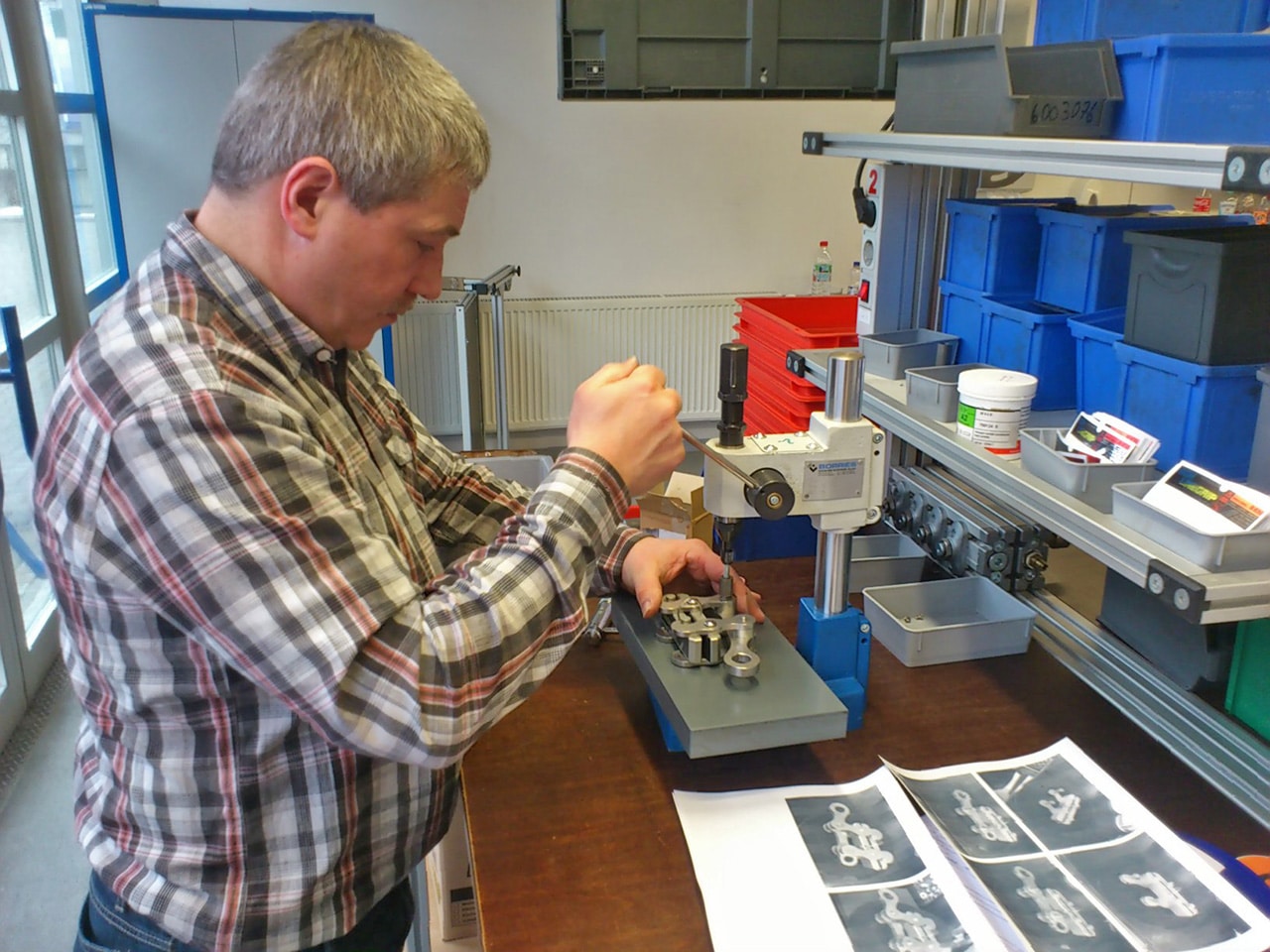

We do not own any manufacturing machines and production facilities. All custom parts are manufactured by external partners in Germany. The whole supply chain is brought together here at headquarters, where assembly is done by the chiefs personally.

3. Optimized assembly techniques.

Over the years we have optimized the manual lineGrip assembly process to a mere 7 minutes, despite the 32 individual parts it consists of. Quality control, adding the manual and spare parts and encasing it in the shell, takes up another 3 minutes, totalling the procedure per unit to 10 minutes, from components to ready for shipping.

Most of the lineGrip’s CNC milled and CNC lathed components are manufactured by Westpfalz-Workshops, and the lineGrip-Shell is manufactured at their sewing shop. They employ and supervise over 2300 people in four factories state wide, and are set up perfectly, to react fast and flexible to our requirements.

ISO-9001 certification guarantees consistent and reliable product quality, and effective production management. It also assures, that only well trained and skilled workers are assigned with manufacturing tasks.

We are proud to support this institution, with its friendly and dedicated people, since 2011.

A total of about 45 people, in 12 companies, are engaged with manufacturing the lineGrip.

The key to a premium product, is dedication and perfection, combined with meticulous quality control, and never ending optimization of the production cycle. To create a premium product, it is essential to entrust only the elite of their craft with the manufacturing of components. This is why we outsource mission critical components to the best of the best, instead of doing it in house, with our own machines.

“I was born 1971 in Zuerich, Switzerland and moved to Asia for 12 years with my family at the age of 7. In Singapore I finished elementary school, and attended the American high school in Seoul, Korea for 3 years, to complete my A-Levels.

“I was born 1971 in Zuerich, Switzerland and moved to Asia for 12 years with my family at the age of 7. In Singapore I finished elementary school, and attended the American high school in Seoul, Korea for 3 years, to complete my A-Levels.

After moving back to Europe in 1989, I enrolled at Novell and Compaq universities in Switzerland, and worked as an IT network engineer in Liechtenstein and Austria until 1999.

Getting the opportunity to help establish two startup companies – one of them a trade-show booth construction – I took the challenge of self-employment, and worked as freelance IT consultant and IT network engineer for the next 4 years. In 2003, I switched to full time key account manager for show-booth construction.

In summer 2006, a friend introduced me to slacklining. We visited the 1st International Slackline Meeting in Scharnitz, Austria (organized by Heinz Zak), where my passion for slacklining was spawned by some motivating talks with Heinz and Chongo Chuck.

At the 2nd edition in 2007, I met Damian Cooksey – one of the best longliners at the time. It was these three people, and the inspiring conversations we had, that sparked my awareness for the demand of serious development of professional slackline gear. Soon after, I started tinkering at solutions for longline- and highline tensioning systems.

One year later, my obsession for developing slackline gear forced me to restructure my life, in order to devote more time to research and development. So, in spring 2009, I quit my job, and founded slackPro!, determined to devote fully to my vision of paving the way for efficient and safe slackline-rigging. The rest is lineGrip history…”

The first warehouse and workshop was established in Andy’s garage in Bruchmuehlbach, Germany – the classical “one-man garage startup”. This 5x4m garage, with a small office space in the appartment, was where he invented and patented the lineGrip, and ran slackPro! for the first 4 years.

In summer 2013, slackPro! moved to new premises, which offered 80m2 of dedicated space for the office, workshop, test-lab, assembly-line and warehouse on the basement floor of Andy’s rental house in Bruchmuehlbach.

By that time, slackPro! had become a full-fledged, globally operating slackline supplier, carrying everything needed for slacklining – from out of the box ready to use longline kits, all types of rigging gear, to webbing and textile goods.

In summer 2015, demand for lineGrips had become too great to handle the 80 additional slackline products without corporate expansion. Therefore, Andy and Artur decided to devote their full attention to the lineGrip, and discontinue the other products, so they founded lineGrip Corp. Ltd. and shut down slackPro!.

Today, LineGrip Corp. focuses on supplying dealers and manufacturers worldwide with lineGrips, enabling them to combine their very own amazing products with the unique lineGrip, and thus give slackliners all over the globe the chance to acquire the best lineGrip-integrated slackline kit conceivable, custom tailored to their personal needs.

New premises – finally a cool studio to combine office, workshop, lab, and warehouse into one spacious and open workspace!

Bruchmuehlbach offered a lot of space – actually too much since discontinuing all the “large space gear” such as kilometers of webbing, chain hoists, and the sorts. Therefore we began looking for new and better suited premises.

In Summer 2019 we finally found what we were searching for: a spacious 3 story house with a friendly, large single-room 80m2 studio and 40m2 storage facility on the top floor. It was simply perfect! So in June 2019 we relocated our business and Andy’s personal residence from Bruchmuehlbach to the about 30km distant Waldfischbach, located in the beautiful Palatine forest, near the French border. Its simply fantastic!