Overview of lineGrip models

Compare the core features of current lineGrip models in the chart below, or scroll down for a short description of each model.

By following the “More about” link below the description, you will get all the detail information about the respective model.

nano

NEW!- ultra light weight

- extra high strength

- fits 1″ webbing

- fits 2″ webbing

- Type-3 rubber

- plate retainer

- safety cap assembly

- screw assembly

- custom colors possible

- includes lineGrip-Shell

- 4 kN safe working load

- 10 kN MBS

- 90 g

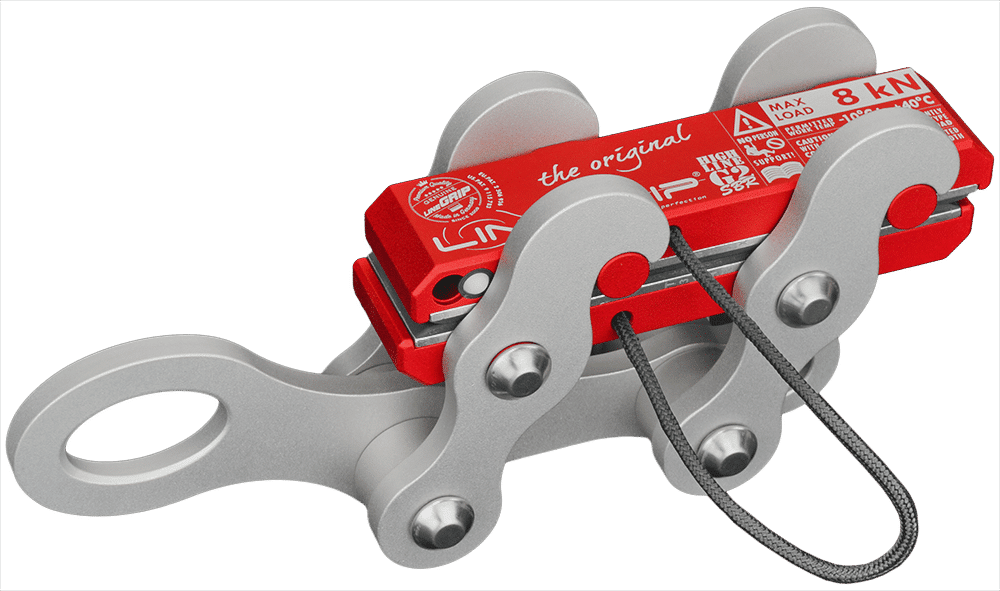

highlineGrip

- ultra light weight

- extra high strength

- fits 1″ webbing

- fits 2″ webbing

- Type-3 rubber

- plate retainer

- safety cap assembly

- screw assembly

- custom colors possible

- includes lineGrip-Shell

- 8 kN safe working load

- 25 kN MBS

- 378 g

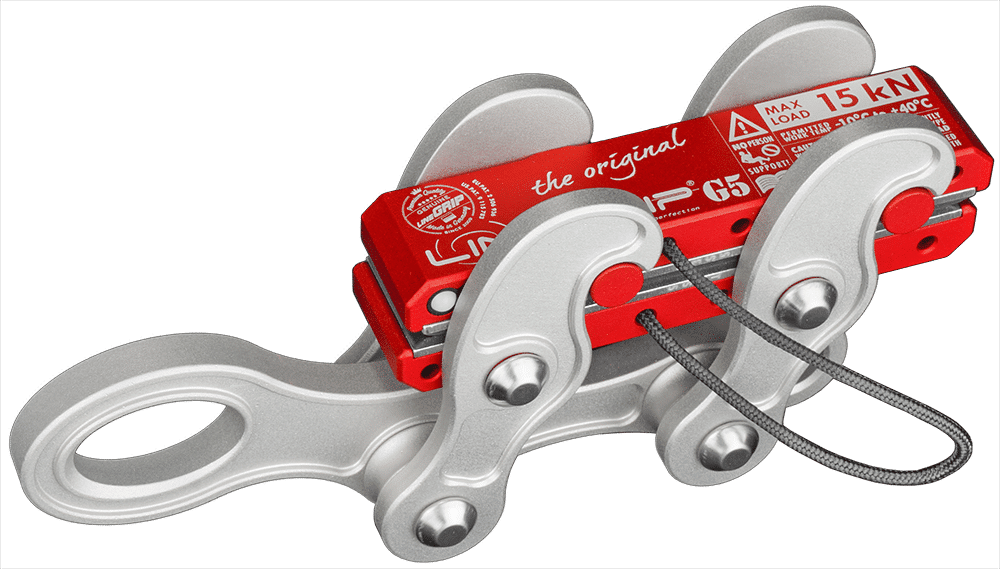

lineGrip G5

- light weight

- extra high strength

- fits 1″ webbing

- fits 2″ webbing

- Type-3 rubber

- plate retainer

- safety cap assembly

- screw assembly

- custom colors possible

- includes lineGrip-Shell

- 15 kN safe working load

- 45 kN MBS

- 418 g

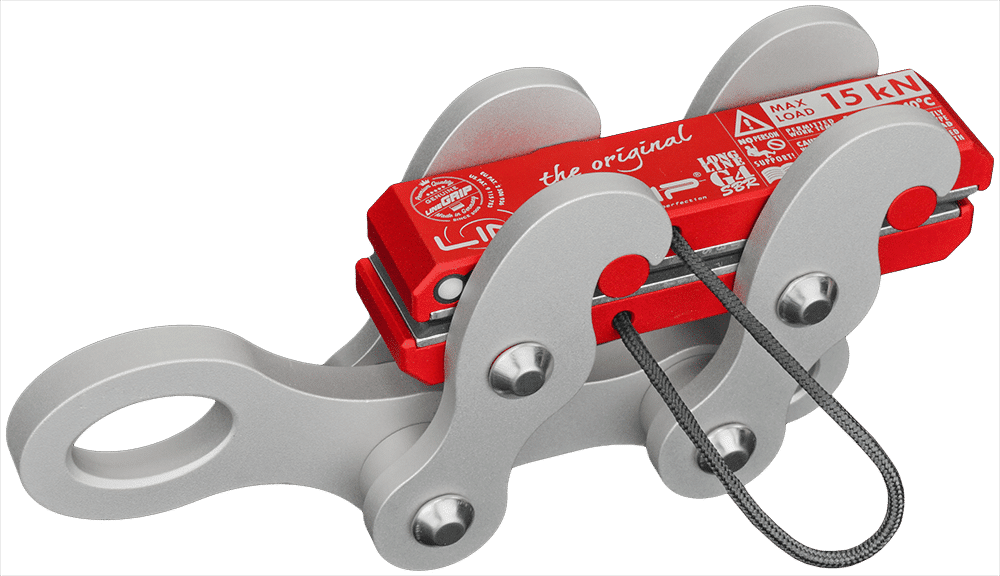

longlineGrip

- ultra light weight

- extra high strength

- fits 1″ webbing

- fits 2″ webbing

- Type-3 rubber

- plate retainer

- safety cap assembly

- screw assembly

- custom colors possible

- includes lineGrip-Shell

- 15 kN safe working load

- 45 kN MBS

- 463 g

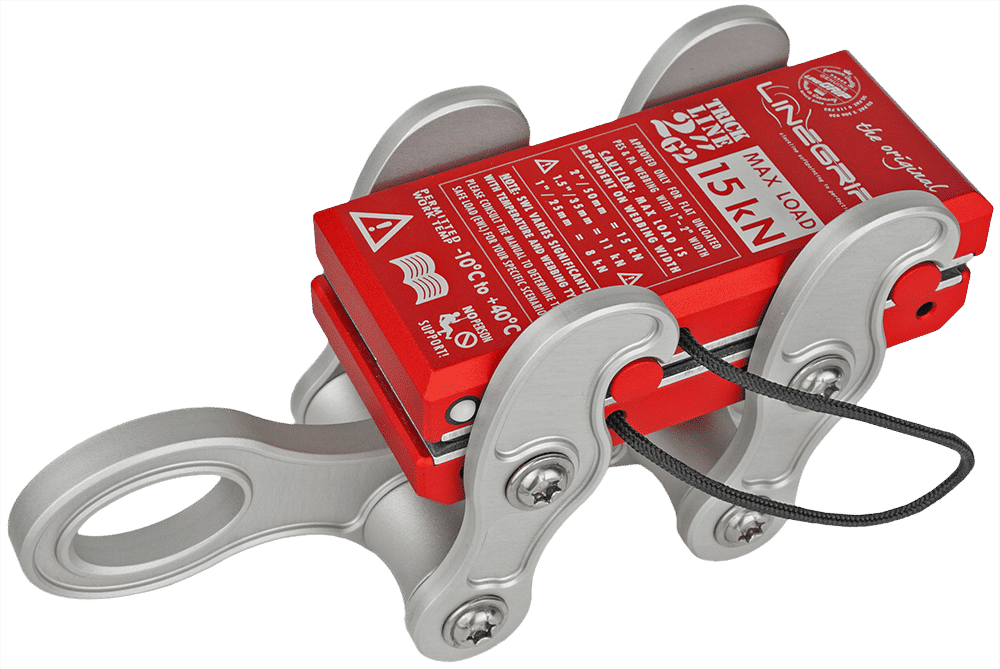

tricklineGrip

2" / 50 mm- ultra light weight

- extra high strength

- fits 1″ webbing

- fits 2″ webbing

- Type-3 rubber

- plate retainer

- safety cap assembly

- screw assembly

- custom colors possible

- includes lineGrip-Shell

- 15 kN safe working load

- 45 kN MBS

- 729 – 785 g

lineGrip nano • 1″

Common alias: “nano”

The lineGrip nano is in all respects a one-of-a-kind.

Its made of Polyamid and based on a whole different technology than all the other lineGrips.

It weighs 90 g, measures 85x 45 x 40 mm and has a working load of 4kN.

The approved working temperature range for the nano is 0° C to +40° C, and it’s approved for 16-26 mm webbing, with a max. thickness of 5 mm.

lineGrip G5 • 1″

Common alias: “G5” or “The 5”

The G5 is the workhorse feather weight, with a max. working load of 15 kN, and an MBS of 45 kN.

It weighs a slim 418 g, and measures 160 x 85 x 47 mm.

All 1″ lineGrips are approved for 24-26 mm webbing, with a max. thickness of 5 mm. The approved working temperature range is -10° C to +40° C.

This lineGrip is only available with SBR technology.

longlineGrip G4-SBR • 1″

Common alias: “LLG”, “lineGrip G4”, or simply “G4”

The longlineGrip is the work horse of the pack, with a max. working load of 15 kN, and an MBS of 45 kN.

It weighs 463 g, and measures 162 x 84 x 45 mm.

All 1″ lineGrips are approved for 24-26 mm webbing, with a max. thickness of 5 mm. The approved working temperature range for all lineGrips is -10° C to +40° C.

This lineGrip is available with the new SBR technology, or as budget model, without retainer (as long as stocks last).

highlineGrip G2-SBR • 1″

Common alias: “HLG” or “highlineGrip”

The highlineGrip is the feather weight, with a max. working load of 8 kN, and an MBS of 25 kN.

It weighs a mere 378 g, and measures 162 x 81 x 45 mm.

All 1″ lineGrips are approved for 24-26 mm webbing, with a max. thickness of 5 mm. The approved working temperature range is -10° C to +40° C.

This lineGrip is available with the new SBR technology, or as budget model, with the legacy retainer-pin (as long as stocks last).

tricklineGrip • 2″

Common alias: “TLG” or “tricklineGrip”

The tricklineGrip has a max. working load of 8 – 15 kN (depends on webbing width), and an MBS of 45 kN.

Despite the enormous dimensions and massive construction in comparison to a 1″ lineGrip, it merely weighs 729 g (785 g for the G1), and measures 160 x 82 x 60 mm.

The tricklineGrip is approved for webbing widths of 25 – 52 mm, with a max. thickness of 5 mm . The approved working temperature range is -10° C to +40° C, typical to all lineGrips.

More about the tricklineGrip >

More about the tricklineGrip G2 >

So, whats the main difference between these four models?

For the tricklineGrip its obviously 2″ versus 1″ maximum webbing width.

The main difference between longlineGrip and highlineGrip is weight and working load.

The highlineGrip is lighter, because it’s parts are slimmed down to save weight and therefore are not as strong as the G4 parts. Additionally the highlineGrip has aluminum load transfer bolts to further save weight. That is why the highlineGrip’s working load is lower.

The lineGrip G5 is in terms of weight in between the G4 and HLG, while still offering 15kN working load. It is also the only model with 3D sculpted components and all-round beveled edges for prestine handling feel.

Apart from that everything, from handling, basic function, over used materials, rubber plates, to leverage-ratio (pressure force between the plates) and safety ratio (3:1) is identical for all lineGrips.